Cavity Wall insulation: do I choose rigid board or bonded bead for my new build?

Cavity walls are typically masonry construction made from concrete block or brick,with an inner and outer leaf (wall) with a gap, or cavity, in between. Inside the cavity, cavity wall ties are installed between the inner and outer leaf to connect the walls together. The original methodology behind cavity wall design was that rain water and moisture would not transfer from the outer leaf to the inner leaf.

One challenge for self builders with a cavity wall construction is the choice between a cavity board or pumped bonded bead cavity wall insulation. The main priority is to ensure you meet the U-values outlined in Part L 2019 Building Regulations (nZEB), which state the maximum elementary wall u-value is 0.18 W/m2K.

When distinguishing between cavity board and pumped bonded bead cavity wall insulation, there are a number of factors to consider:

1. The size of the cavity and which material will ensure you meet Part L 2019 nZEB requirements

The standard cavity width of most new builds is 150mm, with the introduction of Part L 2019 building regulations, we are starting to see cavity widths increasing up to 200mm and beyond.

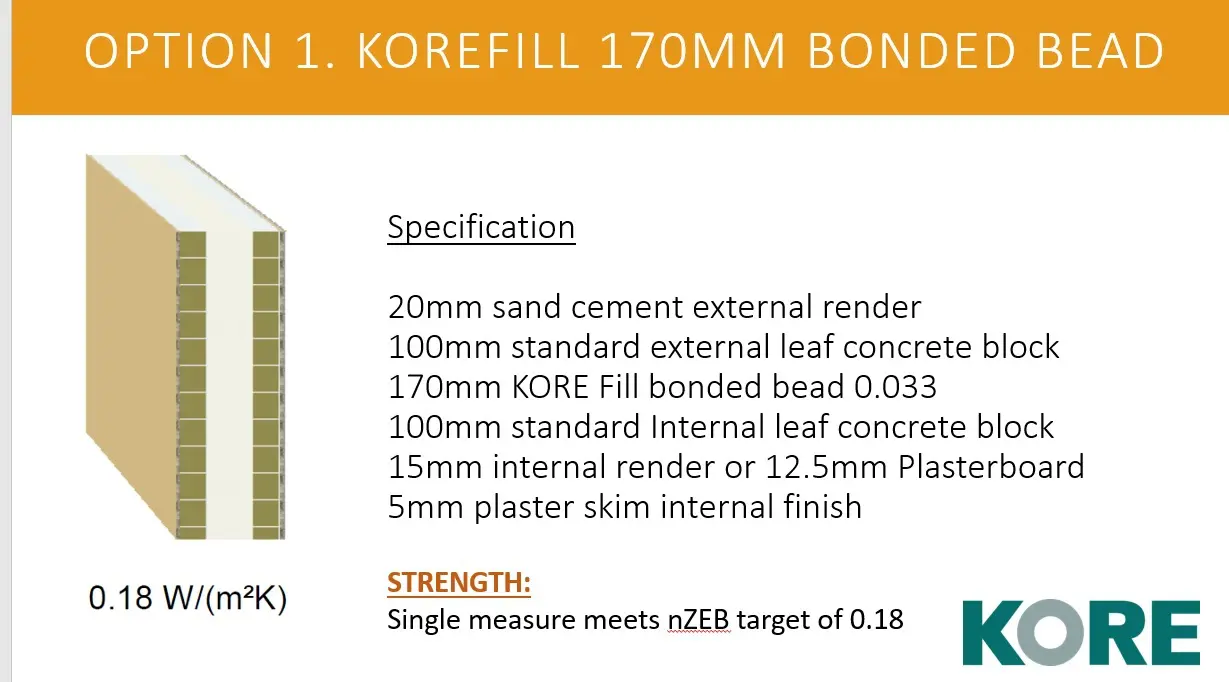

KORE Fill bonded bead cavity wall insulation has been designed to achieve and exceed current building requirements of 0.18W/m2K. KORE Fill Diamond bead with a thermal conductivity of 0.033W/mk can be specified for cavity widths of 170mm to 200mm, achieving the minimum of 0.18W/m2K and in some cases 0.15W/m2K. Using additional insulation internally, which is the norm in some builds, combined with the filled 150mm cavity of KORE Fill Diamond Bead will achieve the new backstop of 0.18 W/m2k.

Every project enquiry we receive at KORE is assigned a sales and technical team member who will provide guidance on how to achieve maximum energy efficiency with our products, with technical guidance on U-values, thermal bridge analysis, condensation risk analysis and more. Once project analysis is complete, we will assign an approved installer to quote and carry out the works. We have an installer network across Ireland who are NSAI, and SEAI approved and registered, as well as KORE trained and approved.

Below is an example of how 170mm of KORE Fill bonded bead can achieve 0.18 W/m2K

2. Elimination of thermal looping, which will ensure maximum efficiency of your cavity wall insulation.

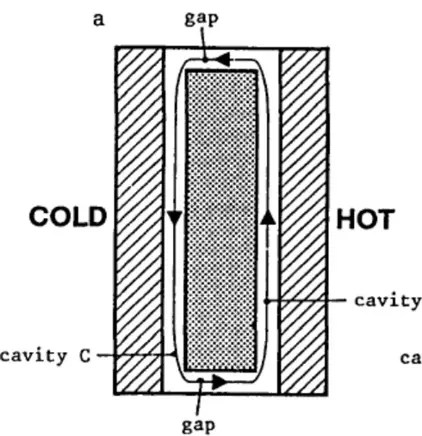

Thermal looping occurs when there are gaps in the insulation, allowing the air to move freely in a loop in the cavity. It is a common issue that occurs when cavity wall board insulation is not installed correctly, and when the cavity is not filled completely. To have maximum thermal performance of the insulation material, and to eliminate thermal looping, there must be no air gaps in the cavity. Incorrect installation of cavity insulation boards (see below) can allow cold air to circulate around the insulation, deeming the material ineffective, and costing the homeowner additional costs in energy spend.

Le Compte (1990) studied the influence of natural convection on the thermal quality of insulated cavity construction, and found it is essential to have the correct application installed to eliminate thermal looping. Le Compte studied the impact of different gaps in the insulation layer and cavity width, and found a cavity with zero gaps present achieved the best U-Value, concluding that the only solution to thermal looping is a complete cavity.

KORE Fill bonded bead cavity wall insulation ensures a complete fill every time. It is NSAI, and BBA approved and certified. The building is measured and assessed to quantify how much bead is needed for full cavity completion, a drilling pattern (see below) is established for a full fill cavity or partial fill. The bonded bead is pumped into the cavity with compressed air, and is solidified with a bonding agent that stops it from moving. As the structure is solid masonry, it will not move, therefore the bead will not move, and will remain intact for the lifetime of the building.

As tested by BBA, moisture does not transfer over the cavity as the bonded bead forms a natural matrix honeycomb structure which allows any penetrating moisture to immediately flow by gravity to weep holes at the bottom of the cavity.

3. Time and Cost

KORE and it’s accredited installers use the lean construction method where waste is minimised and efficiencies are maximised. As mentioned above the building is measured and assessed to quantify how much material is needed, this ensures there is no waste on site, and you only pay for what you need. Cavity boards can have 10-15% waste diverted to landfill, whereas KORE Fill ensures there is no waste on site.

The complete fill can be done in a matter of hours with our experienced installers across Ireland, reducing time on bricklaying by up to 20%. The superior thermal properties of this high performance cavity wall insulation does not diminish over time, contributing to long term energy savings, and reduced heating bills.

4. Registered and Approved Installers

There are a variety of insulation installers around Ireland, however it is necessary to ensure they are NSAI registered and approved. This can be checked via the NSAI registered cavity wall installers list here.

KORE have 25 certified and approved KORE Fill cavity wall insulation installers across the island of Ireland. Each installer is NSAI registered and have been trained by KORE to carry out KORE Fill bonded bead cavity wall insulation installation. KORE carries out quarterly audits and inspections on each company and upskill installers regularly.

Many of these installers also offer other insulation services such as attic and external wall insulation, as well as energy efficiency solutions such as heat pumps and solar PV.

5. Sustainability of the product

When purchasing insulation for your new build, you want to make sure it will last the lifetime of the building, while keeping its effectiveness throughout.

KORE’s Expanded Polystyrene is a sustainable material, made from 98% air, HCFC & CFC free, and will last the lifetime of the building. The embodied energy of EPS is recovered many times over by the energy saved in the building where it’s installed. 1kg of EPS saves at least 400 litres of oil over 50 years when used as insulation.

KORE’s EPS does not degrade over time or lose its performance, it will retain the same thermal properties decades after installation. EPS will not need to be replaced over time, is maintenance free, and if removed from the building, can be recycled and used in other forms.

Using KORE Fill bonded bead cavity wall insulation can help your new build achieve passive house and low energy build standards.

Contact