KORE Fill Cavity Wall Insulation is Expanded Polystyrene (EPS) injected in bead form, along with a bonding agent, into a wall cavity to create an insulating mass

Two options available: KORE Fill Original and KORE Fill Diamond for use in cavities up to 225mm in width

Ensure Part L compliance: Easily meet and exceed current building regulations of 0.18W/m2K

Only pay for what you need – installed by expert installers with zero waste.

-

For New and Existing Buildings

KORE Fill Bonded Bead can be used in full & partial fill applications in both new build and retrofit applications

-

Dramatically Reduce Heat Loss

KORE Fill is injected in the cavity along with KORE Fill Glue to insulate the cavity

-

Cost-effective & transparent

Professional installers ensure you only pay for what’s required – nothing more.

-

Zero-waste

No skip hire required. Zero waste & material is left on-site.

Technical Information

Fully Certified

- Certified to NSAI Agrement 04/0293 (IAB)

- Manufactured to IS EN 13163:2012+A2:2016 and in an ISO 9001:2015 QMS certified facility

- Installed by KORE, NSAI and SEAI Approved contractors

Meet nZEB with KORE Fill

Meet nZEB

- Designed to exceed the requirements of Part L.

- The required U-value for external walls in new builds is 0.18W/m2K.

- Certified for cavities of up to 225mm made with an external render or brick.

- Builders can easily meet the requirements of Part L with the following

|

|

Thermal Conductivity |

Thickness |

U-Value |

|

KORE Fill Original |

0.035W/mK |

180mm |

0.18W/m2K |

|

KORE Fill Diamond |

0.033W/mK |

170mm |

0.18W/m2K |

Exceed Part L

|

|

Thermal Conductivity |

Thickness |

U-Value |

|

KORE Fill Original |

0.035W/mK |

200mm |

0.16W/m2K |

|

KORE Fill Diamond |

0.033W/mK |

200mm |

0.15W/m2K |

Wallboard, Plasterboard, Dabs, Concrete Block, Insulation, Concrete Block, Render

| Cavity Thickness | Material Thickness | Material | U-Value | Thermal Conductivity | Assumptions |

| 150mm | 110mm | PIR (with 40mm cavity) | 0.18 | 0.022 | Best workmanship – Correction level 0 for air gaps |

| 170mm | 170mm | Diamond |

0.18 | 0.033 | Wall ties are double triangle stainless steel, Best workmanship – Correction level 0 for air gaps |

| 150mm | 130mm | PIR (with 22mm cavity) | 0.15 | 0.022 | Best workmanship – Correction level 0 for air gaps |

| 200mm | 200mm | Diamond |

0.15 | 0.033 | Wall ties are double triangle stainless steel, Best workmanship – Correction level 0 for air gaps |

| 150mm | 150mm | PIR (full fill) | 0.14 | 0.022 | Best workmanship – Correction level 0 for air gaps |

| 225mm | 225mm | Diamond |

0.14 | 0.033 | Wall ties are double triangle stainless steel, Best workmanship – Correction level 0 for air gaps |

| The average cost savings when compared to rigid insulation board is approximately 27% to achieve a U-value of 0.18W/m2K. This cost saving does not include the added cost of waste removal from site that may be associated with other cavity wall insulation materials. For more information please contact our technical team or your local KORE Fill Approved Installer. | |||||

New Build – Plasterboard, Block, Insulation, Block, Render

|

Original 0.035W/mK |

Diamond 0.033W/mK |

|

|

Cavity Width |

U-Value W/m2K |

|

|

170mm |

X |

0.18 |

|

180mm |

0.18 |

0.17 |

|

200mm |

0.16 |

0.15 |

|

250mm |

0.13 |

0.13 |

|

300mm |

0.11 |

0.11 |

New Build – Plasterboard, Block, Insulation, Brick

|

Original 0.035W/mK |

Diamond 0.033W/mK |

|

|

Cavity Width |

U-Value W/m2K |

|

|

170mm |

X |

0.18 |

|

180mm |

0.18 |

0.17 |

|

200mm |

0.16 |

0.15 |

|

250mm |

0.13 |

0.12 |

|

300mm |

0.11 |

0.10 |

Retrofit – Partial Fill: EPS Board (0.037W/mK) with KORE Fill Original (0.035w/mK)

|

Year House Was Built |

Cavity Width |

Expected Insulation Level in Cavity |

U-Value |

KORE Fill Original |

New U-Value |

|

1997-2002 |

100mm |

60mm |

0.44 |

40mm |

0.34 |

|

1990 – 1997 |

100mm |

50mm |

0.50 |

50mm |

0.34 |

|

1980’s |

80mm |

40mm |

0.58 |

40mm |

0.37 |

|

1970’s |

40mm |

None |

1.56 |

40mm |

0.62 |

Retrofit – Partial Fill: EPS Board (0.037W/mK) with KORE Fill Diamond (0.033W/mK)

|

Year House Was Built |

Cavity Width |

Expected Insulation Level in Cavity |

U-Value |

KORE Fill Original |

New U-Value |

|

1997-2002 |

100mm |

60mm |

0.44 |

40mm |

0.30 |

|

1990 – 1997 |

100mm |

50mm |

0.50 |

50mm |

0.30 |

|

1980’s |

80mm |

40mm |

0.58 |

40mm |

0.36 |

|

1970’s |

40mm |

None |

1.56 |

40mm |

0.60 |

| Typical Semi Detached House Achieving a U-Value of 0.18 | 110mm PIR Insulation (0.022W/mK) | 170mm KORE Fill Diamond (0.033W/mK) |

| Wall Area | 137m2 | 137m2 |

| Material Costs | ||

| Installation & Labour | Extra charge in addition to the cost of material | Included in the price of material. No additional cost for installation |

| Additional Concrete to Strip Foundation | N/A | |

| Material Savings for Windows & Door Area (16.5m2) | Boards cut for openings – creating waste | |

| Wall Ties | ||

| Sills & Heads for 170mm Cavity | N/A | |

| Average Savings vs. Rigid Board | 27% | |

Cavity Wall Insulation Cost Savings

The following example shows the average cost savings when choosing KORE Fill Cavity Wall Insulation over rigid board PIR insulation. The costings took into account a semi-detached house with a wall area of 137m2 to achieve a U-value of 0.18W/m2K.

Even with a wider cavity (170mm) the cost savings on average is 27%. This figure does not include the cost savings associated with skip hire and waste removal associated with rigid board insulation.

Speak with one of our KORE Fill Approved Installers to learn more.

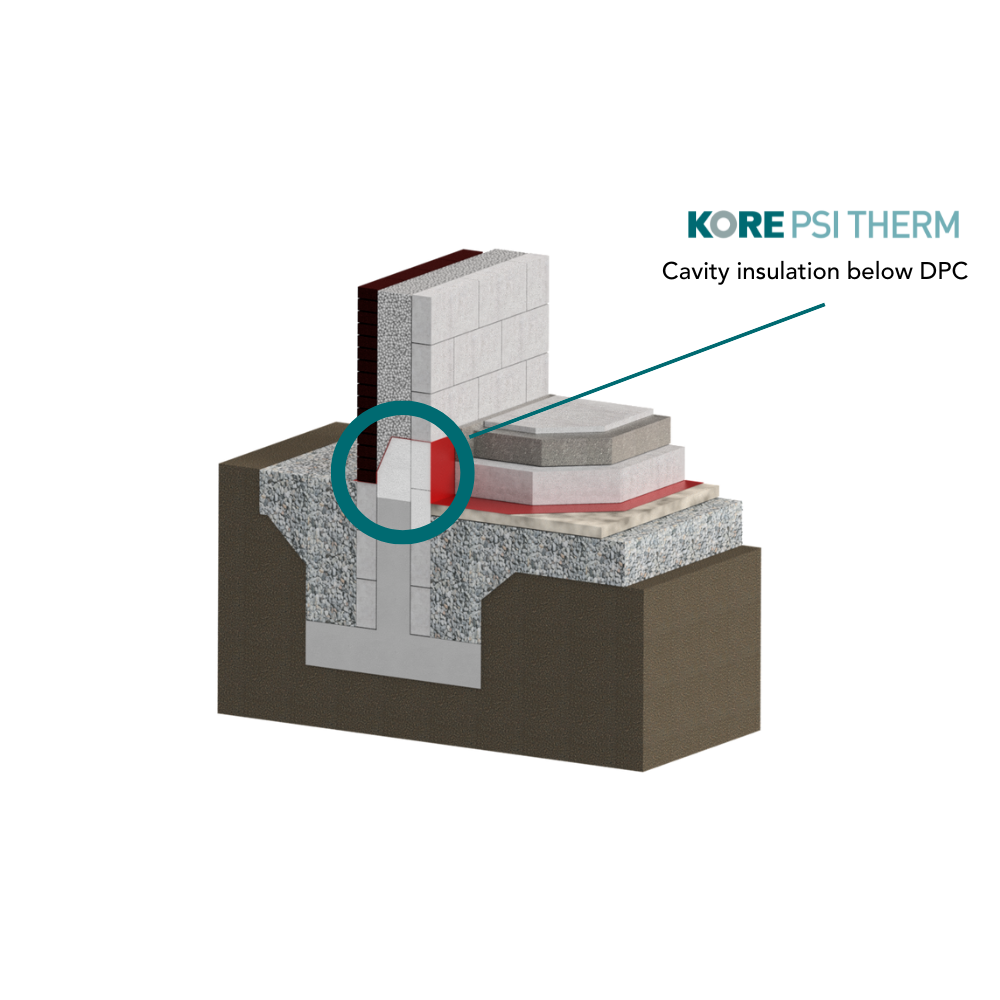

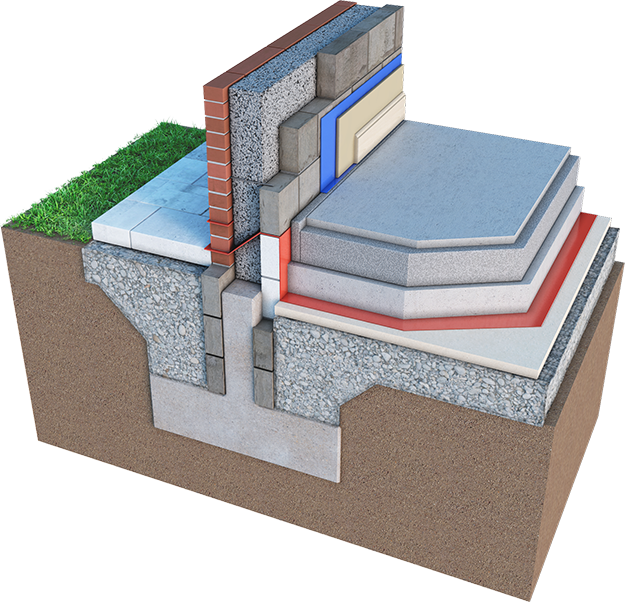

KORE Fill Psi Therm is manufactured from Expanded Polystyrene Insulation and designed to be installed in a cavity wall below the damp proof course (DPC) level. The product eliminates the thermal bridge at the wall-to-floor junction.

The benefits of KORE Fill Psi Therm include:

- Eliminates the wall-to-floor thermal bridge

- Extends cavity insulation below floor slab level

- Improves Psi value

- Inherits all the benefits of EPS, including water and moisture resistance and is unaffected by air infiltration

- Can be fully recycled at the end of its useful life

- Site specific to the required sizes and dimensions