Expanded Polystyrene (EPS) has been in production since 1952. The insulation material is non toxic, CFC & HCFC free, energy saving, high performing and most importantly sustainable, with infinite recyclability prospects. EPS plays a key role in developing a circular economy in Ireland and Europe which we will discuss further in this blog.

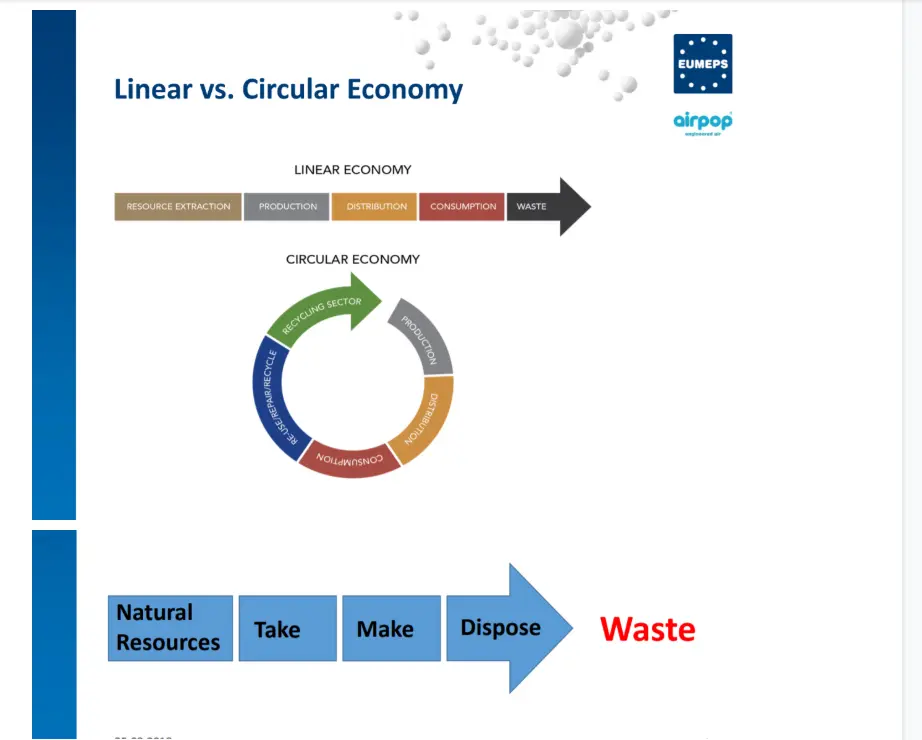

For many years we have all lived in a linear economy where we buy items, use them, dispose of them, and replace them thus increasing landfill, producing toxic waste, degrading the environment, and eating into a finite supply of resources on earth.

According to the association for European Manufacturers of Expanded Polystyrene (EUMEPS), the voice of EPS in Europe, it is imperative we strive for a circular economy for environmental resilience & protection and European sustainability.

The European Construction Industry Federation “Construction 2050: Building tomorrow’s Europe today” initiative states that buildings are responsible for just under 40% of energy consumption, and 36% of CO2 emissions in the E.U. In Ireland alone our building stock uses 7% more energy when compared to the EU average, and due to our reliance on fossil fuels such as heating oil, our CO2 emissions are at a staggering 58% above average. In our fight against Climate Change, we have the power to achieve objectives set out in Ireland’s Climate Action Plan 2019, and the Sustainable Development Goals by using renewable energy sources, sustainable construction materials, and increasing our renovation/retrofit of existing buildings.

From a perspective of a circular economy, we must look at using products that offer minimum waste, are sustainable when in use, and recyclable at the end of its life cycle. KORE’s Expanded Polystyrene (airpop) is a sustainable material whose embodied energy is recovered many times over when the material is used as insulation. Our EPS is made of 98% air, CFC & HCFC free, chemically inert, will last the lifetime of the building, and can be recycled when not in use. Our EPS insulation does not degrade over time, no waste is generated via wall, roof or floor insulation as we measure exact plans, and in any case where waste is generated, we recycle in our factory to make more insulation for future customers. If EPS needs to be removed from a building at any point, the material can be recycled and reused in a wide variety of products and applications as outlined similarly in the video below by EPS-Foreningen, who look at the sustainability of an EPS fish box.

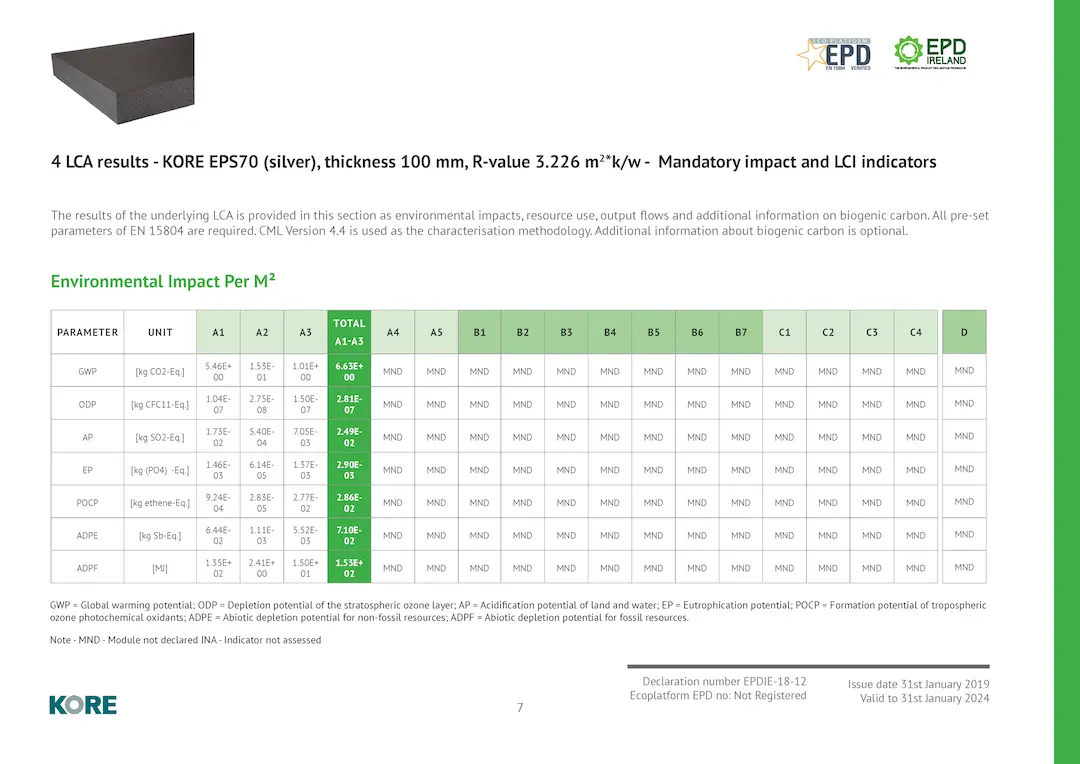

KORE believes in the importance of a circular economy for our planet and our customers and was the first company in Ireland to obtain ISO 14001:2015 Environmental Management Certification in 2016. KORE were also the first Expanded Polystyrene manufacturer in Ireland to gain anEnvironmental Product Declaration (EPD) for our EPS. An Environmental Product Declaration is a standard that sets out the environmental impact of a product through its life cycle. The essential aspects of the EPD is that our product is made of 98% air, is sustainable throughout its usage, and is recyclable when not in use. Did you also know that using products with an EPD can get additional credits in Building Sustainable Assessment schemes like the Home Performance Index, LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method). Please find below a life cycle analysis result for our KORE EPS70 Silver.

Our commitment to the environment and the sustainability of our products falls in line with the voluntary pledge EUMEPS submitted in 2019 to the full circularity of EPS products. Unlike other insulation materials, expanded polystyrene is easily recycled in several ways and does not degrade or deteriorate over time. This key benefit of EPS was recently outlined by IFEU (Institut Fur Energie) & Nature Plus in an independent study conducted on insulation sustainability where they found that EPS insulation boards were the most advantageous choice for sustainability due to their recyclability.

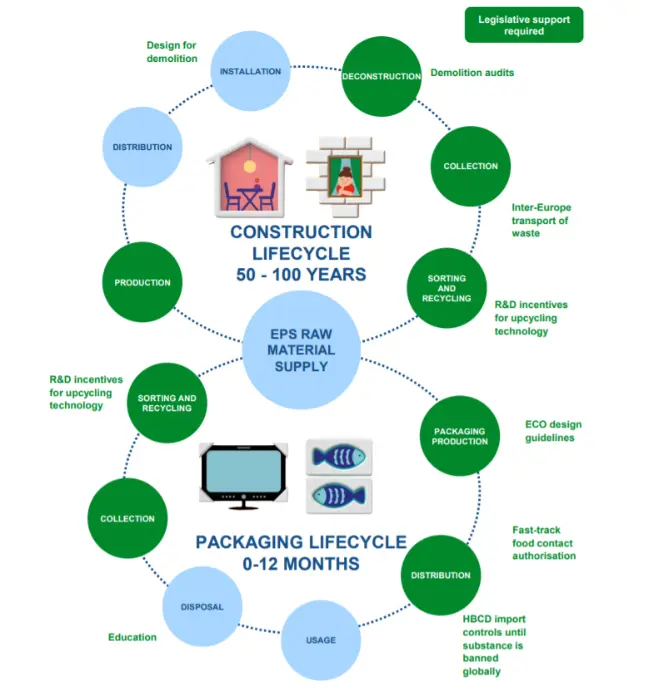

Below you will find a diagram from EUMEPS voluntary pledge outlining the lifecycle of EPS for construction and packaging, that will provide a circular supply chain, feeding into an overall circular ecosystem.