Thames Tideway Tunnel, London Case Study

KORE case studies offer an inside look at how our EPS solutions perform in real-world applications. The following case study in London, England features KORE’s EPS Void Formers.

Case Study Details

Project Name: Thames Tideway Tunnel- Hammersmith Pumping Station

Products Used: KORE Void Formers

Main Contractor: FK Lowry Piling

Main Client: Tideway

KORE Sales Rep: Andrew Butler (@KOREAndrew)

-

Void Formers KORE Insulation -

Hammersmith Void Formers by KORE Systems

About the Thames Tideway Tunnel Project

The Thames Tideway Tunnel project is currently underway in London. The new “super sewer” will support London’s existing sewer system which, whilst still in excellent condition, can no longer cope with the capacity of London’s expanding population spilling millions of tonnes of sewage into the tidal section of the Thames every year. When complete, the Tideway project will help to protect the River Thames from overflow, diverting sewage into a tunnel instead of the river itself. The Hammersmith Pumping Station site is one of seven work sites within the west section being delivered by the BAM Nuttall, Morgan Sindall, Balfour Beatty joint venture.

KORE Void Formers with Millimeter Accuracy

FK Lowry, a piling contractor part of the Lagan Group, chose KORE Void Formers for the Tideway project with their being undertaken with the Hammersmith Pumping Station work site in West London.

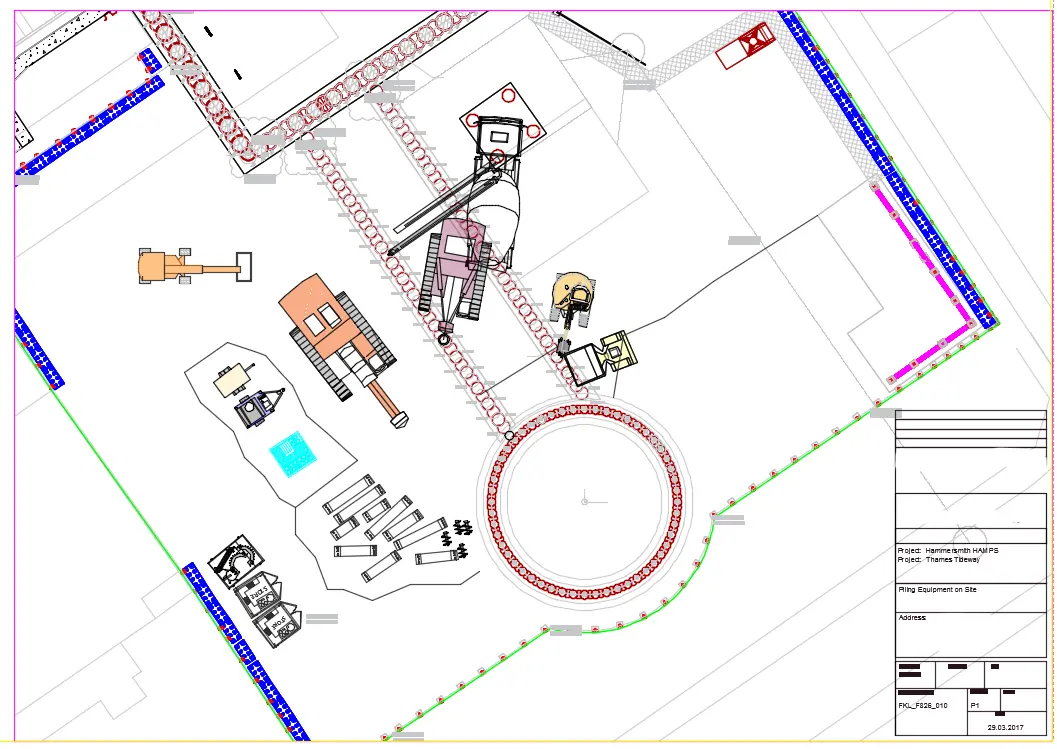

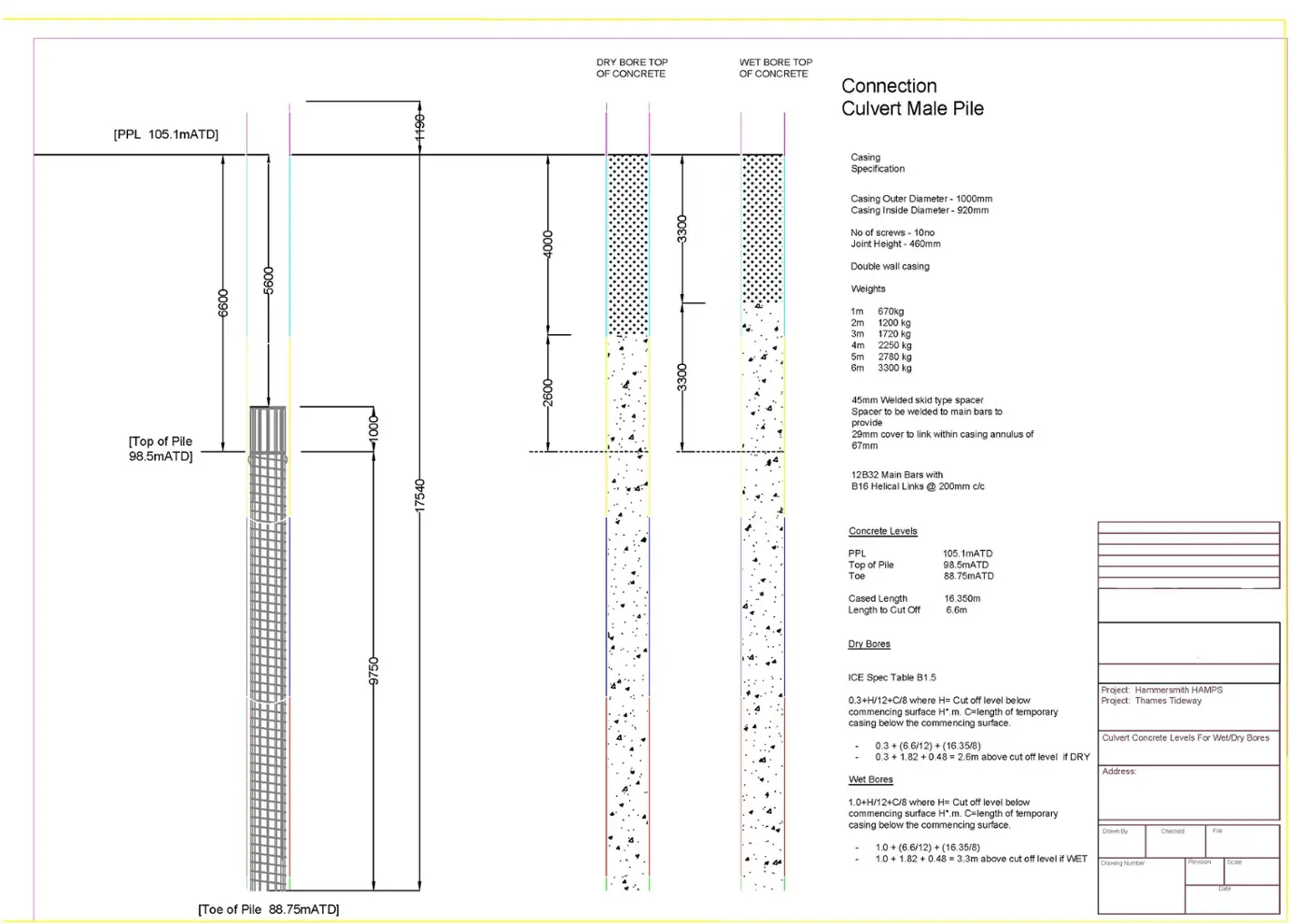

FK Lowry chose KORE EPS70 White Void Formers, creating a temporary formwork to facilitate the piling works. The voids required precision accuracy down to the millimeter, as the project was very precise with high specifications including radius layouts and void radius up to 1200mm.KORE Void Formers were used to construct the RC secant pile guide walls on three sections, including:

Hammersmith Pumping Station combined service overflow (CSO) shaft

Connection culvert between the interception chamber and CSO drop shaft

Interception Chamber

Additional technical information can be found in the detailed plans below.

Andrew Butler

Technical Sales Manager

Andrew Butler has been a Technical Sales Manager for KORE for the past five years. Andrew graduated from Dublin Institute of Technology and has a varied background in engineering and architecture, giving him the perfect mix of skills and education needed to excel in his role as a technical sales manager for KORE. Andrew is also our in-house BIM expert, having worked closely with Waterford Institute of Technology on all our details. You’ll see Andrew around the north of Ireland, including North Dublin, Louth, Cavan, Galway and Northern Ireland.

You can reach Andrew by email or by phone on +353 87 226 8483.