Windmill Development Case Study

KORE case studies offer an inside look at how our EPS solutions perform in real-world applications. The following case study in Clonsilla, Dublin features KORE’s EPS Void Formers. The project is delivered by Elliott Group on behalf of Kimpton Vale Developments Ltd.

Case Study Details

Project Name: Windmill Development Project, Clonsilla, Dublin 15

Products Used: KORE Void Formers

Main Client: Elliott Group

KORE Sales Rep: Donovan Ogle

A Word from the Customer

The KORE Technical Team were very helpful throughout the design process. They produced 3D visuals & schedule of a very complex void former arrangement.

They engaged with our design team & responded promptly to all correspondence. The approved material was delivered on time & everything fit like a glove which allowed us to meet our project goals.

About The Project

The Windmill development project is currently underway in Clonsilla, Dublin 15.

The development is comprised of 211 apartments within three 6-8 storey blocks.

This project is delivered by Elliott Group, on behalf of Kimpton Vale Developments Ltd.

KORE Void Formers and Customised Specification

Elliott Group, a prominent building and civil engineering company, chose KORE Void Formers for the Windmill project to form a concrete slab over podium level. Elliott’s engaged KORE to manufacture the void formers to the exact specifications needed for this complex design.

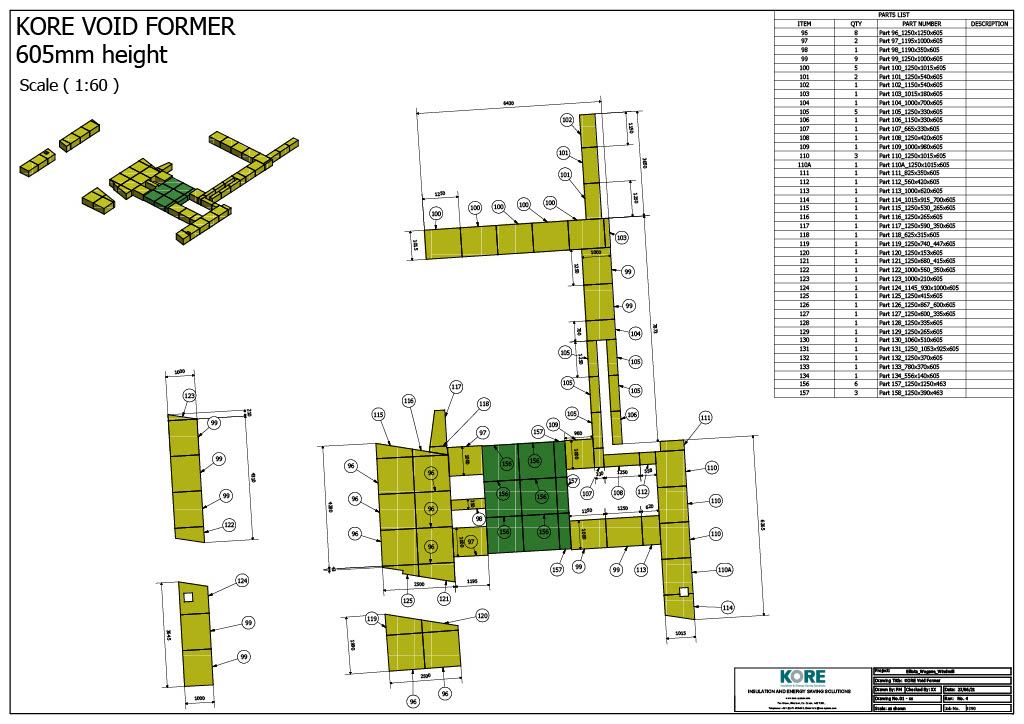

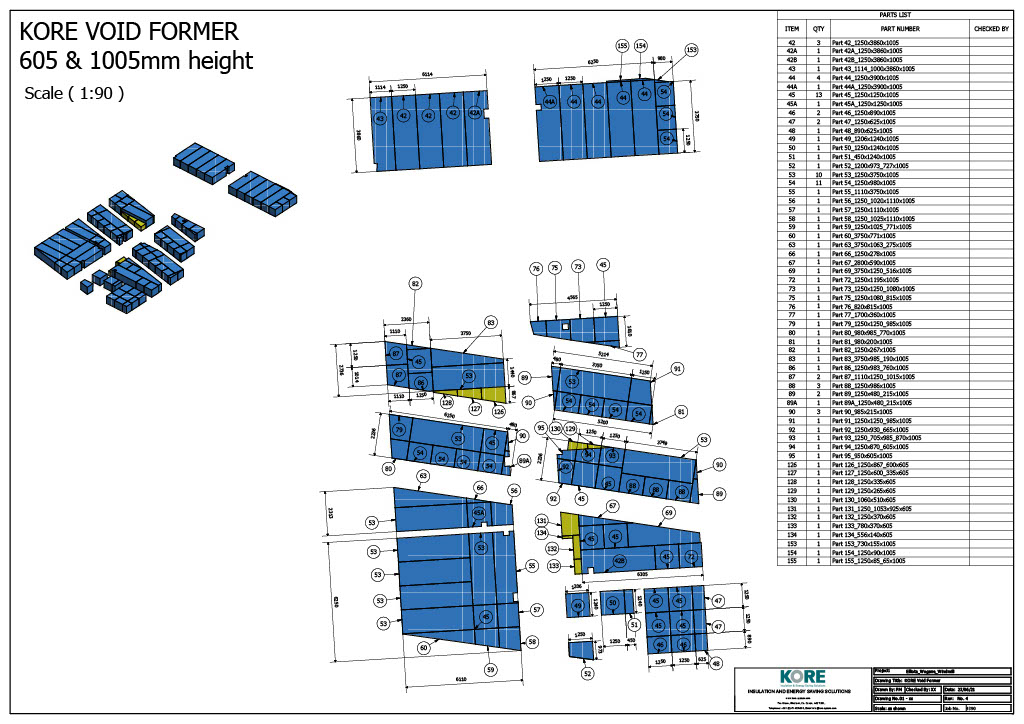

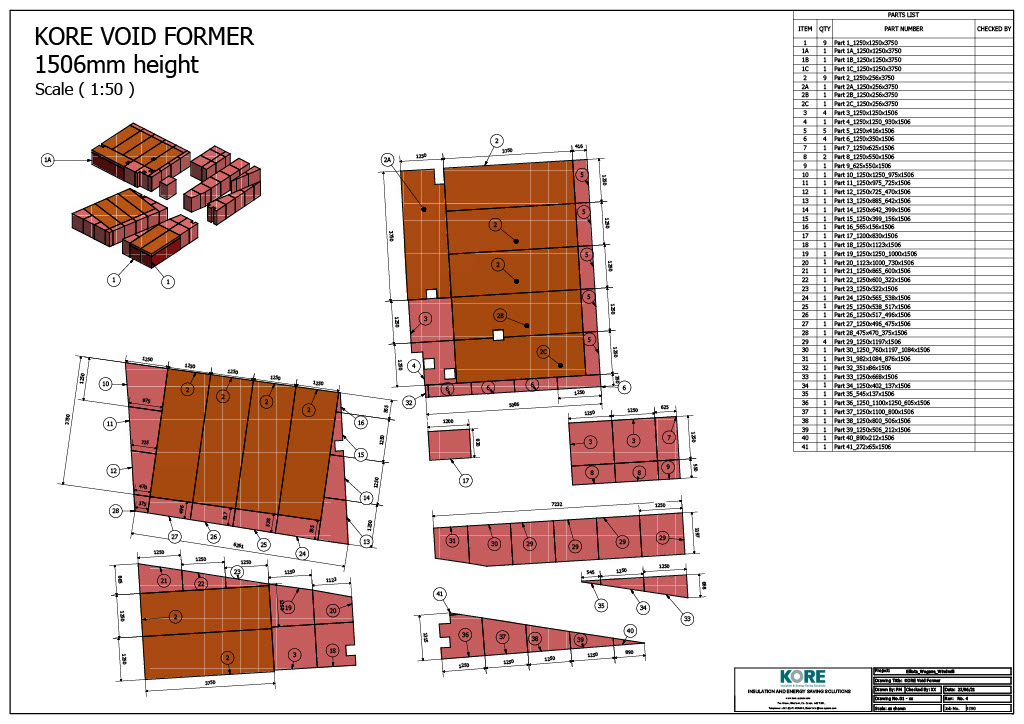

Elliott Group chose KORE EPS100 White Void Formers, enabling a cast in-situ concrete floor to be formed above the podium concrete slab below. To achieve millimetre accuracy and the required specification of the different floor to soffit heights, KORE manufactured over 150 individual pieces of varying sizes and shapes, allowing the ground floor to be cast to the correct FFL. As another benefit of EPS, the concrete can be poured directly onto the material without the need for a DPM separation layer. The long term physical performance of EPS also makes it a natural choice with defined compressive strength.

EPS is a very well suited product for this application and can be profiled and cut in the factory to match the site specifications. Using EPS void formers solved the issue faced when dealing with infill of existing sites, which can challenge a contractor. As the EPS void formers are lightweight, they are easily placed on site without the need for machinery, creating a temporary formwork to facilitate works. They are less labour and time intensive, avoiding the need for levelling and compacting stone. The voids required precision accuracy down to the millimetre, as the project was very precise with high specifications, including radius layouts and void radius up to 1200mm.

Additional technical information can be found in some of the detailed plans accompanied.

Photos of works

Donovan Ogle

Regional Sales Manager

Donovan Ogle has been a Regional Sales Manager for KORE since the beginning of 2020. Donovan has over 6 years of experience in the construction and insulation industry selling to merchants, builders, and end-users in his role as regional sales manager. Donovan primarily covers Ulster & Northern Ireland, and areas of Connaught, including Mayo and Sligo.

You can reach Donovan by email or by phone on +353 87 1842192 or +44 75 84763862.