Summary of the Lecompte (1990) Paper: Energy – Insulation: The Influence of Natural Convection on the Thermal Quality of Insulated Cavity Construction

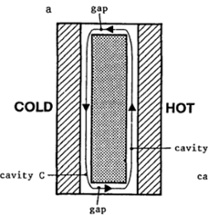

In basic terms Lecompte (1990) found that the correct application of insulation in a cavity is vital to avoid heat transfer by natural convection or air flows through the insulation layer. Simply put, bad workmanship that leaves air gaps in the insulation and/or cavity had a devastating effect on the actual U-value W/m2K of a partially filled wall. This movement of air is also called a Thermal Loop as the air moves around the cavity in a loop. The image below shows the movement of air as represented by the arrows.

Testing Air Flow Around the Insulation

Lecompte placed a 2m test wall into a calibrated Hot Box – Cold Box and took more than 100 measurements of the different combinations of gaps in the insulation layer and cavity widths on both sides of the insulation. The gaps in the cold side was 4cm and 1cm on the warm side. The air gap at the top and bottom of the insulation were changed and results were monitored. The following U-value results were found:

| Width Top Gap mm | Width Bottom Gap mm | Measured U-value W/m²K | |

| Test 1 | 0 | 0 | 0.34 (101%) |

| Test 2 | 3 | 3 | 0.54 (158%) |

| Test 3 | 10 | 10 | 0.65 (193%) |

In simple terms, a 3mm gap in the insulation leads to a reduction compared to the calculated u-value of 58%, while a 100mm gap had 93%.

The Solution

All is not lost however as Lecompte concluded that a solution to this problem is to fill the cavity construction completely, thereby eliminating both residual cavities. When the cavity is filled with insulation the movement of air around the insulation material does not occur. The results above show that when there is no gaps in the insulation the calculated U-value will equal the measured U-value. In other words the insulation is preforming to the specified standard as prescribed by industry experts.

Our Solution: KOREFill Bonded Bead will fill the cavity construction completely and therefore the movement of air in the cavity is non existant. In addition KOREFill Bonded Bead is often said to flow like water, it fills even the small little dimples found on the surface of the block face. Once filled the Bonded Bead the product will remain in situ and fill the cavity sapce for the lifetime of the building. Specialist KORE Installers use specialist equipment to pump the EPS insulation material into the cavity.

Visit our KORE Fill Product Page now and find the KORE Installer closest to you.

Lecompte (1990 pp.254) finished by saying “it is clear that good workmanship is a major priority in obtaining an insulated cavity construction of high thermal quality”. So ensure you call in the KORE Insulation experts.

Source: Lecompte, J. 1990. Energy – Insulation: The influence of natural convection on the thermal quality of insulated cavity construction. Building Research and Practice, 18(6), pp. 349-354.