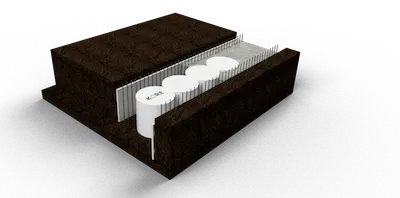

KORE’s Void Formers and Void Fillers are structures made of Expanded Polystyrene (EPS), which is a light weight material that has substantial weight bearing load capacity. Void formers decrease the volume of concrete, reducing weight while increasing the strength. Void fillers are designed to fill a void with Expanded Polystyrene and are left in-situ. Available in a range of compressive strengths to suit the needs of your project, KORE’s EPS Void Formers are used extensively throughout the construction industry for major works such as motorways, underpasses, shopping centres, foundations and embankments. KORE Void Formers are suitable for domestic and commercial applications.

Why choose KORE Void Formers and Void Fillers ?

KORE Void Formers are the ideal solution for applications that require the reduced weight of concrete when left in-situ. KORE Void Formers can also be used temporarily as part of a formwork system. KORE Void Formers and Fillers allow the construction of a building or bridge to be lighter in weight and also helps to stabilise them. KORE Void Formers are made from Expanded Polystyrene (EPS), the same high performance material used for our extensive range of insulation solutions. Made from 98% air KORE EPS is lightweight, versatile, water and moisture resistant, rot-proof and will not degrade over time. KORE Void Formers are manufactured to the specification required from each project and profiled before delivery to site. KORE Void Formers can also be cut on site without the need for any specialised equipment. KORE EPS can be used for both void former and void fill applications.

Standard Formwork Solutions

Arch Formers KORE Arch Formers provide temporary support to curved masonry structures until the structure is able to support itself. Arch formers are made from EPS, lightweight and can be reused where identical elements are needed. Spiral Staircase Formers KORE EPS can be used for spiral staircase applications where complex designs require formwork. KORE Spiral Staircase Formers are customised to your exact project requirements and can be reused (i.e. between flights of stairs). Column Formers KORE Column Formers are perfect for projects that require custom in-situ reinforced concrete columns. Made from KORE EPS, KORE Column Formers are reusable, allow for high quality exposed concrete finishes and manufactured to your exact specification.

Formwork for Ribbed Concrete Floors

Trough Moulds KORE Trough Moulds are the perfect solution for constructing ribbed concrete floors with one-way spanning. KORE Trough Moulds reduce concrete requirements, can achieve longer spans than traditional flat slabs, are lightweight, reusable and are manufactured to exact specification. Waffle Moulds KORE Waffle Moulds are the perfect solution for constructing two-way spanning ribbed concrete floors. Offering reduced concrete volumes and the ability to achieve greater spans, KORE Waffle Mould are lightweight, reusable and built to exact specifications.

Piling Solutions

Guide Wall Formers KORE’s EPS Guide Wall Formers are used to form an in-situ, sacrificial guide wall to improve the accuracy of pile guide wall construction. Sacrificial guide wall formers are for single use in many civil engineering and construction applications. Secant Pile Wall Construction KORE EPS can be utilised for secant pile wall construction (i.e constructing intersecting reinforced concrete piles). Secant piles are reinforced with steel rebar or steel beams and provide a number of benefits, including an increase in construction alignment flexibility and wall stiffness when compared to other solutions like sheet piles.

Temporary Access and Safety Solutions

Temporary Ramps KORE EPS easily creates temporary ramps when access to floors of differing heights is required. KORE’s temporary ramp solutions are bespoke and manufactured to exact specifications, easy to install, lightweight and can be repositioned and reused as necessary. Rail Platforms KORE’s EPS rail platforms allow for safe and easy crossing between platforms. Available in different grades of EPS, our bespoke rail platforms can easily accommodate varying loading requirements.

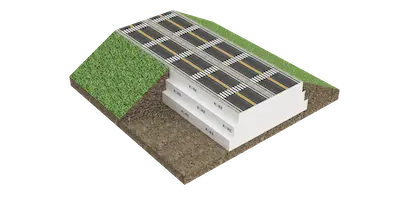

Embankments

Road Embankments KORE EPS can easily be used as a light fill material in road embankment applications. KORE EPS for embankment applications helps with both stability and and settlement issues with soft subsoil conditions and offers a reduction in load on the subsoil and settlement. Slope Stabilisation KORE EPS provides slope stabilisation as a soil substitute fill to reduce driving forces. KORE Expanded Polystyrene does not degrade or absorb moisture, making in the ideal solution for slope stabilisation applications.

Additional EPS Applications

EPS for Marine Pontoons KORE EPS works exceptionally well for marine pontoon applications due to its buoyancy and water resistance. KORE EPS can be used for a variety of floating structures including docks, rafts, floating shelters, pontoons and slipways. J Feed Troughs KORE EPS can be used to form concrete J feed troughs and other troughs that need to be durable, weather-resistant and strong.

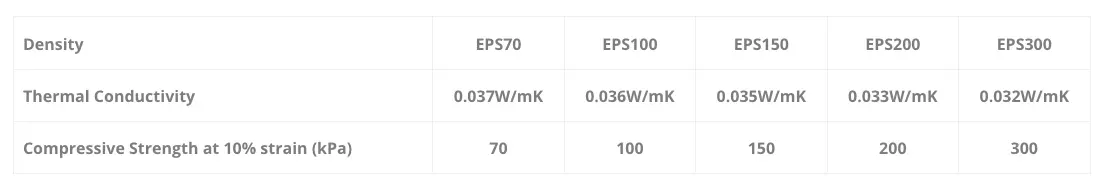

KORE Void Former technical information

KORE Void Formers and Void Fillers comply with EN 14933 & EN13163. For more information please contact our technical team.

EPS: An environmentally sustainable material

In 2016, KORE became the first company in Ireland to obtain ISO 14001:2015 Environmental Management Certification. Our system helps us manage both immediate and long term environmental impacts our products, services and processes may have. KORE was also the first Expanded Polystyrene Manufacturer to receive an Environmental Production Declaration certified by the Irish Green Building Council and EPD Ireland. This makes achieving LEED, BREEAM and Home Performance Index certification easier. The manufacturing process is also CFC and HCFC free. KORE EPS is also chemically inert, so it can be handled safely on-site without the need for specialised equipment. As the number of recycling collection points continues to grow, EPS can also be recycled at the end of the building’s lifespan.

KORE Void Formers on-site

KORE Void Formers have been used in a variety of civil engineering applications, as well as in bridges, shopping centre foundations and motorways, including passages of the M50 in Dublin and the foundation of the Red Luas Line. One of the larger projects our Void Formers were used on was the Thames Tideway project in London. Read a full case study on this project here.