What is Expanded Polystyrene (EPS)?

Expanded polystyrene, or EPS, is a plastic material derived from crude oil used in a variety of applications, including thermal insulation in buildings, civil engineering applications and decorative mouldings and panels. Outside of the construction industry EPS is used as protective packaging for consumer items, void formers and packaging for food and pharmaceuticals, among a wide variety of other industrial and consumer applications.

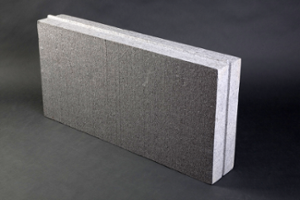

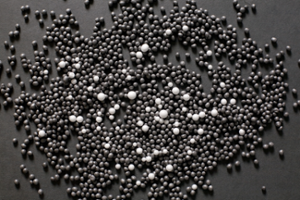

Building insulation EPS can be found in all areas of the home, including roof and attic insulation, cavity wall insulation, floor insulation, exterior wall insulation and insulated concrete formwork. Expanded polystyrene is available in loose fill form (beads) for cavity wall insulation applications, and as panels for internal and external insulation projects. EPS can be used to retrofit an existing home or building, or it can be used as part of a new build.

Although made from crude oil, EPS accounts for less than 0.1% of crude oil’s total usage. In fact, 83% of all crude oil is turned into another form of energy, while an additional 4% is used in the production of plastics that end up in our landfills.

What is Expanded Polystyrene’s Impact on the Environment?

The impact EPS has on our environment is negligible compared to other pollutants. In its finished form EPS is made up of 98% air, leaving 2% as crude oil derived plastic, making it one of the most effective insulators available in Ireland. The European Manufacturers of Expanded Polystyrene, or EUMEPS, estimates that for every litre of oil used to produce EPS insulation, 150 litres of oil is saved in heating costs over the lifetime of the building (pg.18).

Buildings are one of the main contributors of greenhouse gas emissions. In Europe alone our buildings account for more than 40% of our total energy demand. More than half of this demand is used for the purpose of heating and cooling buildings we live and work in. Insulation is a cost effective method to reduce our energy demand and greenhouse gas emissions, whether retrofitting existing structures or insulating properly during a new build.

Expanded polystyrene does not degrade over time, is unaffected by moisture and is non-toxic. Unlike other forms of insulation EPS does not produce airborne fibres or use chlorofluorocarbons (CFCs or HCFCs) at any stage during its production or use. Even better, no waste is created during the production of EPS. Any leftover or flawed material is recycled back into the production process and reused.

Sustainability of Expanded Polystyrene

EPS accounts for less than 0.1% of all material found in our landfills today. Due to the nature of the product and the way it’s made, most leftover material can be recycled during the production process or used in a different application rather than thermal insulation. Since EPS is water-resistant and does not degrade over time it can last the lifetime of a building, reducing our current need to recycle the product. In the event a building is demolished and the product removed EUMEPS suggests several ways EPS can be recycled, including:

- Reuse in the production of new EPS insulation

- New non-foam consumer products and applications such as plastic cutlery, CD cases and fence posts

- As an additive to make light-weight concrete blocks for construction purposes

Used EPS is collected and recycled at several locations across Europe. These collection points have been set up by EPS organisations and local authorities in over 25 jurisdictions, all who have signed an International Agreement on Recycling. Recycled EPS reduces the need to use raw material to produce new product and help keep EPS out of our landfills and in our home. While rare, expanded polystyrene that cannot be recycled can be burned at the same efficiency as that of a power plant.

Unless substantial changes are made to the way our buildings are insulated energy demand in Europe will double by the year 2050, causing an increase in CO2 production and the continued warming of our environment. EPS is a cost-effective, light-weight and durable material that is easily recycled at the end of its useful life. Any impact EPS has on the environment is easily outweighed by the reduction in greenhouse gas emissions and energy demands saved in buildings and homes insulated with expanded polystyrene.

Interested in offering KORE Expanded Polystyrene products to your customers? Enquire today.

Source: Sustainable Construction with EPS Insulation.” EUMEPS. N.p., n.d. Web. 23 Apr. 2014.