Virtually eliminate thermal bridging by wrapping the entire foundation in a continuous layer of EPS.

Enjoy a fully engineered system that offers U-values as low as 0.10W/m2K

Go from blinding layer to concrete in as little as two days*. Perfect for large-scale developments, reducing install times and maximising efficiencies on-site.

Reduced embodied carbon of up to 30% compared to a traditional foundation system.

U-values:

|

|

Perimeter/Area (m2) |

||||||||||

|

0.10 |

0.15 |

0.20 |

0.25 |

0.30 |

0.35 |

0.40 |

0.45 |

0.50 |

0.55 |

0.60 |

|

|

U-Value (W/mk2) |

|||||||||||

|

|

0.076 |

0.085 |

0.091 |

0.094 |

0.097 |

0.099 |

0.101 |

0.102 |

0.103 |

0.104 |

0.105 |

-

Less worry about ground conditions

Fully engineered to meet the ground conditions of any site.

-

Choose your build type

Suitable for nearly all construction types including ICF, steel frame, traditional block and timber frame houses.

-

Reduce your costs

Up to 40% less concrete required, reducing costs for both material & labour.

-

Make underfloor heating work smarter, not harder

Over 3x more heat retention & 13% less energy usage compared to a traditional screed layer in a typical foundation.

-

NSAI Certified

Build with Ireland’s first NSAI-certified Insulated Foundation System with a proven track record.

TECHNICAL INFORMATION

- Download KORE Insulated Foundation Design Guide >>

- Download the KORE Insulated Foundation System nZEB Leaflet >>

For Engineers: A Finite Element Analysis & Transient Thermal Analysis are available upon request. Please contract us for more information.

For Builders & Developers: Cost comparison reports for a strip and raft foundation are available. Contact us for more information.

Site Studies: View our latest site studies on a large-scale development in Tullamore and Kilcock.

Ireland’s First Certified Insulated Foundation System

- NSAI Certified – Irish Agrement Board Certificate Number 20/0424

- Manufactured to I.S. EN 13163:2012+A2:2016 by an ISO 9001:2015 QMS certified manufacturer

- Signed-off by a qualified structural engineer on every site

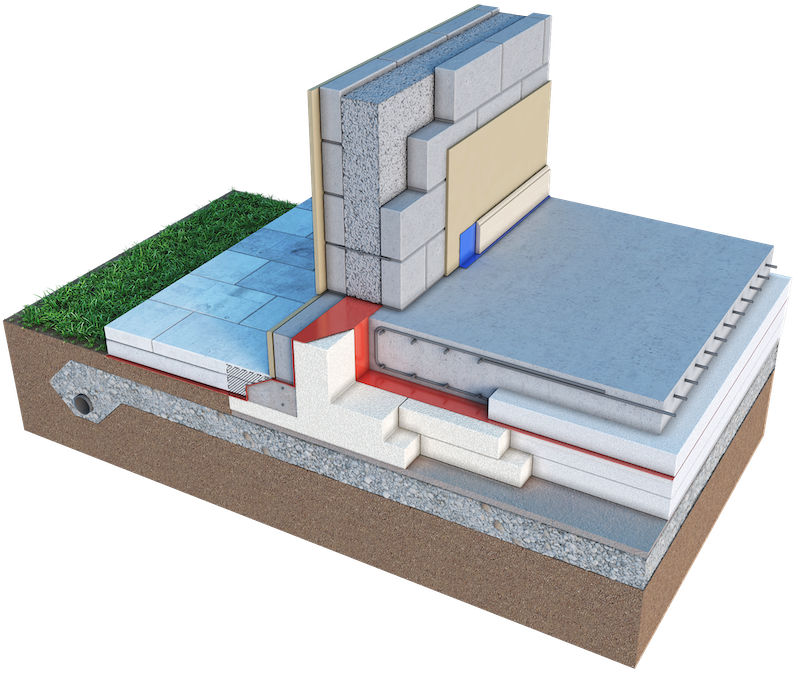

How Does the Insulated Foundation System Work?

Rollover the image above to see the different components of the KORE Insulated Foundation System

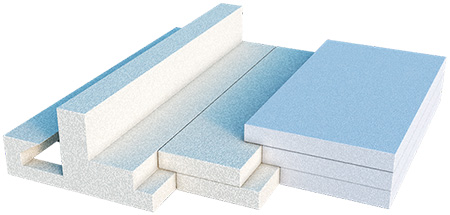

The insulated foundation system consists of three EPS components: KORE Floor EPS100 White, EPS200 White and EPS300 White, providing an efficient insulation layer to reduce heat loss through concrete ground floors. An in-situ concrete slab is poured on top.

To form the perimeter of the foundation, edge-profiled EPS300 ring-beam forms are laid out on the blinding layer in precise positions and held together using U pins or PU adhesive. EPS300 sheets are positioned under internal load bearing and/or party walls. EPS100 sheets are placed inside the perimeter and laid with closely butted joints. Additional layers are fitted with break bonded pattern and fitted tightly at the edges and around any service penetrations.

Radon/DPM is laid between or below the layers of EPS, with joints taped to prevent the passage of ground moisture. Reinforcement is installed according to the drawings and schedules by the design engineer.

Installing the KORE Insulated Foundation System

The short video below details the typical installation process for the KORE Insulated Foundation System. For more information, or to become a registered installer, please contact us.

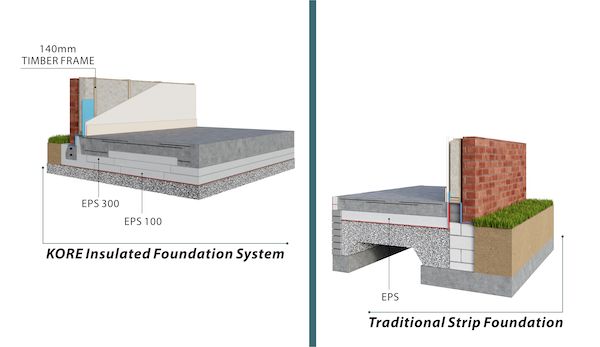

More Cost Effective

Using a pair of semi-detached homes as an example, KORE’s Insulated Foundation System is 13% more cost effective compared to a strip foundation, and 16% when compared to a raft foundation. These cost savings can be attributed to:

- Simplicity of excavation and construction

- Elimination of blocks and block-layers

- Elimination of expensive formwork

- Elimination of additional insulation and screed to form the finished floor

Increased cost savings can be expected with repeated use due to the speed of fitting, especially on larger sites where bases can be prepared in batches. In addition, the finished floor and subfloor become one, meaning just one concrete pour, eliminating the need for pouring screeds and the preliminaries and attendances that go hand-in-hand.

For more information, cost comparisons can be provided with an itemised breakdown. To request these reports please contact us directly.

Eliminate the wall-to-floor cold bridge

KORE’s Insulated Foundation System virtually eliminates the critical wall-to-floor cold bridge. EPS is used to wrap the junction in a continuous layer of insulation, ensuring the wall to floor thermal bridge is eliminated and there is no break in insulation between the non-insulating materials.

Reduced concrete requirements

KORE’s Insulated Foundation System reduces the amount of concrete required for the foundation between 50 and 60 percent. This reduces your costs for both material and labour, making an insulated foundation a cost-effective solution for your next build.

Ideal for large-scale developments

KORE’s Insulated Foundation System is the ideal solution for large-scale developments. This innovative technology allows builders and developers to go from blinding layer to concrete in as little as two days, reducing time, labour and cost typically associated with traditional foundations.

Provides seriously low U-values

KORE’s Insulated Foundation System can achieve U-values much lower than those required by Part L 2021 and nZEB. Typical U-values provided by the foundation system range from 0.10W/m2K to 0.11W/m2K depending on the specifications of the project. Our technical department can provide U-value calculations as part of the quotation process.

Suitable for most ground conditions

KORE’s Insulated Foundation System is suitable for a wide variety of ground conditions and is specifically engineered to meet the requirements of the site. The foundation system can be used in soft ground conditions as the system allows the weight of the structure to be transferred throughout the slab.

Exceptional compressive strength

KORE’s Insulated Foundation System works much like a traditional raft foundation. The EPS element is specifically designed and cut to suit the building type for installation. The foundation’s exceptional compressive strength makes the product suitable for both domestic and commercial applications.

Heavy internal loads can easily be accommodated onto the insulated foundation by thickening the slab to 100mm and by installing EPS300 under the thickened slab area.

Suitable for a variety of build types

KORE’s Insulated Foundation system is suitable for most construction types. This includes insulated concrete formwork (ICF), steel frame, traditional block and timber frame houses. KORE’s Insulated Foundation can also be used with off-site builds. Speak with a member of our sales or technical team for more information.

Complete with Environmental Product Declaration

KORE EPS has received a third-party verified Environmental Product Declaration from EPD Ireland and the Irish Green Building Council. This lifecycle analysis can be used towards achieving low energy building standards like LEED, BREEAM and Home Performance Index (HPI).

10 February 2020

10 February 2020

03 December 2018

03 December 2018

26 November 2018

26 November 2018